Water plays an important role in coffee, making up most of the beverige, and there are a few big issues involved with coffee, starting at origin with growing, processing, and at the brewing stage with quality of water effecting flavours in different ways, and scaling up espresso machines..

What I wasn’t so aware of is, as I drink my V60 Harar, I am also unknowingly using 100’s of liters of their precious water!

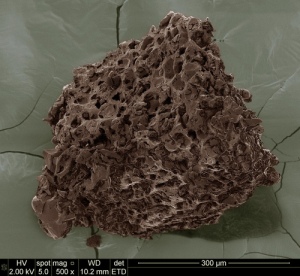

According to this study waterfootprint.org for every cup of coffee we drink, 140 liters of water is required to grow and produce it!! 99.66% of this water is for growing, with only 0.34% accounting for wet processing.

Origins like Harar, where rainfall is so scarse they don’t wash any coffee, this issue is particularly big, to think for each cup of coffee we drink, 140L of clean rain water went into coffee trees- and not to people!

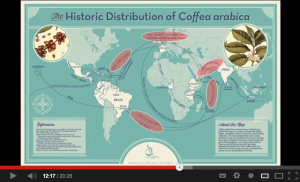

When a product is exported there is resources used to produce it, ‘Virtual water’ is water used to grow a product which is then exported, depleting the origin of this resource and product.

We all consume water, The water levels on the planet will stay the same, but where it falls, how its used, and how polluted it is when we try to consume it is a different story.

This may sound a bit academic, but really we have a similer situation here in NZ with huge dairy production for milk powder export using mass water for irrigation etc, with water shortages are becoming more common. Seventy percent of New Zealand’s irrigated land is in Canterbury, where two big irrigated dairy farms can use more water than the whole city of Christchurch.

Estimates by the NZ Water Rights Trust state at least 500 litres of water is needed to produce a single litre of milk—possibly much more. Australia’s Commonwealth Scientific and Industrial Research Organisation puts the ‘water footprint’ of a dollar’s worth of milk at 1,470 litres.

Water stress is a reasonably now concept, it is when the annual water supplies drop below 1,700 cubic metres per person per year, and is occurring in many places these days when 50 years ago it was commonly believed clean water was an infinite resource.

Water Justice: as the research points out, when talking about water problems in coffee, there is a much bigger and separate topic than pollution of rivers through processing, or scale building up in espresso machines, as we are essentially exporting water out of coffee origins, at over 100L per cup of coffee.

As far as I know, small lot farmers who we buy from, the water used in growing the coffee is all rain fall. But for larger plantation, water irrigation for growing may be happening, perhaps mainly in robusta and commodity coffee, where farming is more extensive and mechanized.

What this means for coffee farmers, ‘virtual water export’ is obviously hard to quantify, this issue is common to all products, but has different effects with some many factors in different countries. But regardless it is a real issue which we play a role in.

What role can we play: perhaps part of our responsibility from the “developed world” is to promote, share and support the use of technology and its management.

This is happening through the co-op mechanism using farmers shared resources to build facilities for cleaning water. But it is still not common place among our co-ops, as many farmers have backyard micro wet mills.

So this is really quite a big picture problem, with no answer to how to change where rain falls, or where products are grow, but never the less, an interesting topic.